deltour@deltour.biz

- Milling heatsinks

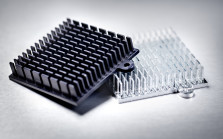

Milling heatsinks

Processing heatsinks

- Milling heatsinks

- Anodising and chromating of heatsinks

- Drilling and tapping heatsinks

- Processing sand-cast products

- Engraving and screen printing

- Interface: material and gluing

- Other processes

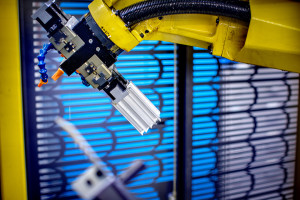

- Robotization

- Machines

- Measuring chamber. Measuring with a tolerance of 1.9 microns

- Product design

- Thermal testing heatsinks

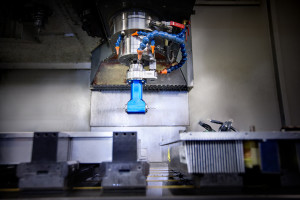

Unable to fit the heatsink into the enclosure? Would you like to have a heatsink adjusted so that components can be attached? We modify heatsinks by milling exactly according to you specifications. We mill larger series on CNC-operated milling machines, with or without robotic loading.

Custom-made hole patterns are very popular. Send us your drawing!

Flattening for optimal heat transfer

A flatness of 0.04 mm per 100 mm of length is often necessary in order to achieve optimal heat transfer from a component to a heatsink. Extruded heatsinks are rather rough themselves. Heat paste can only be used to deal with the differences on a small scale. We are able to provide you with heatsinks that have the desired flatness for disposing of all heat.

No burrs

Heatsinks and enclosures should never have burrs. Even one small piece of metal in your sensitive electronics might do a lot of harm. All milling done at Deltour is deburred in a neat and thorough way.

Options milling heatsinks

We provide all kinds of milling:

- custom-made hole patterns

- milling with a radius as from 0.5 mm

- milling with or without robotic loading

- from small to large milling

- from simple to very complex milling

- from a small number of pieces to very large series of heatsinks

All our milling is done in-house, which means that we can offer you rapid service and competitive prices.

Not everything is done with computer-operated machines. It can be easier and faster sometimes to drill a hole by hand!