Enclosures for electronics

An electronics enclosure often needs a cooling capacity as well. Integrating the heatsink into the enclosure is not a problem for us there. For specials we will take a look at your specifications with you and we will try to find the most effective and efficient solution.

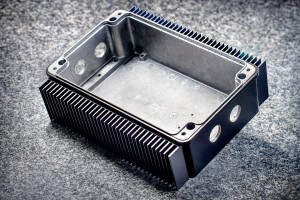

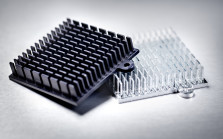

Enclosure with a cooling function

- With cooling fins, milled from a solid material

- With glued cooling fins, from a solid material

- Processing existing enclosure, using external cooling fins

- Sand-cast

- From separate pieces of sheet metal, with integrated heatsinks, if applicable, for instance 19″ enclosure

- Manufacturing prototypes

This enclosure meets severe EMC requirements and cools extremely well. The cover is attached with 74 bolts and the entire casing is silver-plated.

Deltour’s DEF94 is perfect for creating a cost-efficient, simple enclosure and for equipping processed end plates with entries for cables and plugs.

Our partner provides us with sand-cast enclosures that we post-process when accurate sizes are necessary. Sand-cast products are generally rough and inaccurate. We are experienced in finish-turning and milling these products.